Nine Alternative Wall Systems For Your New Home

1) Lightweight Steel Framing

Lightweight steel framing consists of cold-formed galvanized steel “C” sections for joists, studs, and rafters. The steel segments come in various depths and gauges so that extra load capacity can be achieved by changing the gauge while keeping the depth the same. Insulation is placed in the wall cavity, with at least some insulation placed on the outside of the studs to reduce thermal bridging. The primary target for lightweight steel frame houses is a professional builder.

Lightweight steel framing is strong, dimensionally stable, and is an easy-to-work-with framing system. This framing system won’t warp or twist, and this results in straight walls and square corners. The materials used in this wall system are not susceptible to termite damage. The steel studs can be pre-cut which results in less waste being generated, and the waste that is generated can be recycled. A large percentage of steel studs are made with recycled material.

2) Structural Insulated Panels

Structural insulated panels (SIPs) are panels with a core of rigid foam insulation between an exterior and interior skin. The most common materials used for the skins are structural OSB (Oriented Strand Board) or plywood. The foam cores are composed of expanded polystyrene, extruded polystyrene or polyurethane. The two skins, in combination with the integral insulation core, carry all of the loads of the structure. The foam insulation keeps the two skins aligned, acting as the web and providing the insulation value. Professional builders are the primary target market for SIPs.

The advantage of SIPs are that they are energy efficient, installation is fast, and the walls are straight and smooth for the interior finishes and exterior cladding. There may be some limitations under high loading conditions and/or concentrated loads. Extra moisture protection such as rain screen protection, may be required. Also, some training is needed to install the system.

3) Insulated Concrete Forms

Insulated concrete forms (ICFs) are hollow blocks or panels made of expanded or extruded polystyrene that are stacked into the shape of the exterior walls. There are connection ties between the inner and outer forms, which are usually steel or plastic. Reinforcing steel is then installed in the cavity between the inner and outer forms, and concrete is poured into the cavity. The foam form becomes part of the wall and remains in place, thus providing insulation value to the wall system. Both the owner/builder and professional builders have shown interest in this type of wall system.

The ICF wall system is easy to install, quite energy efficient, has good sound and fire rating characteristics, and is very durable. However, the cost of a house with ICF exterior walls is typically a few percent higher than a standard wood-frame house. Also, the increased weight of the exterior walls may require larger footings to accommodate the increased loads.

4) Post and Beam

Post and beam construction consists of a series of vertical posts or columns supporting horizontal beams to form a structural framework. Posts are located at each corner of the building and are usually spaced evenly between the corner posts to support the loads from the roof. The post and beam are usually left fully visible to the inside. Post and beam framing is typically installed by professional builders.

Post and beam construction provides the structural components of the building, and at the same time provides an interior finish that many homeowners find attractive–the entire interior of the house does not require load-bearing walls, allowing for a very open design. The major drawback of this system involves the drying of the wood. Shrinkage can result in cracking and movement due to the drying process. The design of the members, including consideration of wind loading, will require the services of a design professional.

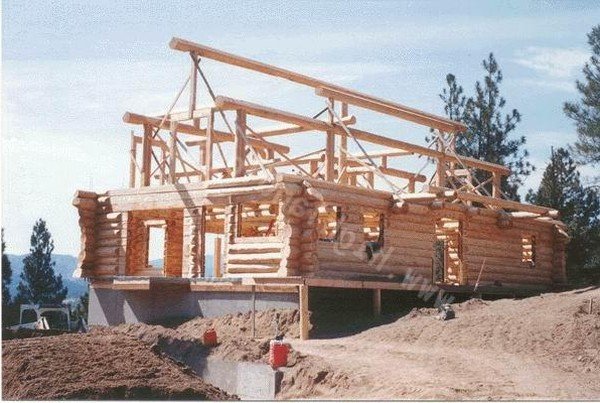

5) Log

In recent years, log homes have made the transition from seasonal to year-round residence, and today, the majority of log homes are being built for year-round occupancy. This has resulted in larger and more sophisticated structures, plus the recognition that building a log home is far more complex than building a weekend cabin. Handcrafted log homes are best suited to owners/builders who are skilled in the use of tools, are physically fit, and have time and patience.

A log house is one of the most aesthetically satisfying homes in which to live. With a good foundation to protect the wood and a wide overhang to shelter against moisture, a log home is very durable and can last for generations. However, building a log home requires skill, is very time-consuming, and is not low-cost. In addition, log homes require more maintenance than brick, vinyl, or aluminum-sided houses.

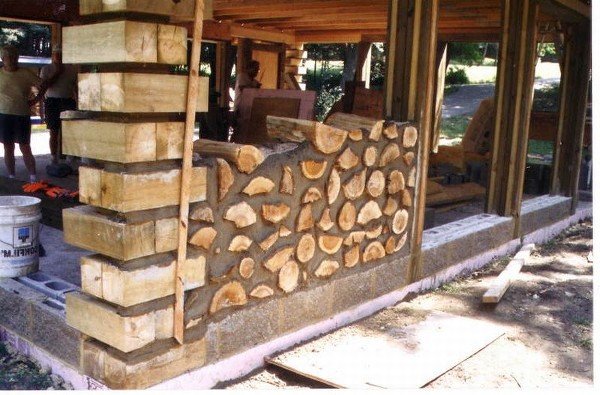

6) Stackwall

The stackwall system, also known as cordwood masonry, roundwood, and log-end construction, is a building technique in which short logs are stacked side by side like firewood, with the spaces between them usually filled with insulation and at the ends, a cement mortar. The log-ends themselves establish the width of the wall and are exposed to both the interior and exterior surfaces. Stackwall homes are more likely to be constructed by owner/builders, and the economically and environmentally conscious.

The key advantages of stackwall construction are economics, ease of construction, resource efficiency, and ecological harmony. The cost of building can be considerably less than a standard wood-frame house, depending on how much labour is provided by the owner/builder and what materials are used. The main drawback to this system is that it is very labour intensive and takes more time to build than a conventional house.

7) Straw Bale

Straw bale construction uses baled straw from wheat, oats, barley, rye, rice, and other grains to build walls, which are then covered with plaster. This technique has been recently revived as a low-cost, environmentally friendly alternative for building highly insulated walls. There are two commonly applied building techniques using straw bales: post and beam and load bearing. Straw bale homes are suitable for most markets but tend to be built by owners/builders.

Environmentally, economically, and in terms of efficiency, straw bale houses offer many advantages. Straw is a natural, affordable, and annually renewable building material. However, careful attention to details during and after construction is crucial to avoid moisture problems. High moisture content in bales can provide a habitat for fungi and can lead to decomposition within the wall assembly. The recent adoption of straw bale construction may not be readily accepted by building code officials, warranty programs, and the home insurance industry.

8) Manufactured Wood

Manufactured wood wall systems are similar to traditional wood framing, with the substitution of manufactured studs for traditional dimensional lumber studs. The manufactured studs include I-Joist, finger-jointed studs, Laminated Strand Lumber (LSL), and Parallel Strand Lumber (PSL). LSL and PSL members are typically used for beams, columns, and lintels. I-Joists are mostly used in floor systems, and finger-jointed studs have similar structural characteristics to dimensional lumber.

LSL and PSL members can be cut to virtually any dimensions and to any length. The manufactured product has a significant increase in strength over dimensional lumber. LSL members can be substituted for traditional studs; PSL members are not typically stud material. Finger-jointed studs are made from short lengths of dimensional material that are joined with adhesives.

The primary advantage of wall systems using manufactured wood studs is the uniformity of the material, which results in walls that are very straight and will not warp and twist in the future. Also, LSL can be used in tall walls with the same size and spacing as dimensional lumber, but with the capability of handling axial loads in combination with wind loads. The main drawback to manufactured wood wall systems is the cost. The studs can be up to double the cost of traditional wood studs.

9) Earth

Earth wall construction is an ancient form of building, and includes techniques such as rammed earth, compressed earth block, adobe, cob, and earth-sheltered. In the rammed earth method, damp soil mixed with cement is compacted in enclosed formwork, similar to that of cast-in-place concrete, and cured. Compressed earth blocks can be manufactured on-site using a variety of block-making machines. The same soil is then used in the mortar for binding the blocks together into walls. The primary target for earth construction is owners/builders who want the satisfaction of building a home using indigenous, recyclable, low-cost materials that are less damaging to the environment.

The main advantages of earth construction are thermal mass and hygroscopicity. The thick wall of a rammed earth home makes it less susceptible to the effect of extreme outdoor air temperatures. Earth walls absorb the extra moisture in the air and release it when there is not enough. Other advantages include durability, reduced exterior maintenance requirements, excellent fire and sound resistance, and resistance to wood predators, fungus, and rot. However, earth wall construction is not suitable for all climates and locations. In addition, the initial cost for a rammed earth home is higher than for a standard wood-frame house.

Conclusion

Research should be undertaken before deciding to use an alternate wall system. The first step is to review the full report and other publications to get a better understanding of a particular system, and some of the alternatives. Another step is to visit construction sites where an alternative system is being installed and talk to one or more builders. Feedback from homeowners is also valuable. The Internet offers the means to access valuable sources of information. In addition to Web sites maintained by various industry groupings, some sites offer feedback from users that describe both positive and negative experiences.

Autoclaved aerated concrete (AAC) and cellular lightweight concrete (CLC)are two more alternative wall systems for the home. Greentec Construction Technologies is one company I know of that makes molds and equipment for CLC products. Using their SupaBlok molds (https://greentecct.com/block-molds/), interlocking dry stacked blocks can actually be made on site without the need for electricity.

I’m glad you talked about different construction materials and their features. Recently, my wife and I started to think about our dream house. We want to build it from the ground up, so we’ll definitely need to learn about construction supplies, and your article will help us with that. Thanks for the information on concrete blocks and how their installation process.

I like how you mentioned that it is important to consider durability when planning. My cousin mentioned to me last night that he is hoping to find a reliable earth home builder for their desired home layout and asked if I have any idea what is the best option to do. Thanks to this informative article and I’ll be sure to tell him that he can consult a trusted earth home builder as they can answer all his inquiries.

How about prefabricated, uniform, 48″ x 48″ x 6″ (of 2×6 lumber) wooden “crates” finished on 1 side with OSB or T-111 plyood siding? The matrix created by these boxes would result in grid pattern of sistered 2×6 lumber ready to accept wiring and 2 pieces of 24″ insulation.

1 man could erect that in a hurry on a concrete pad. Glue/screws each unit, each floor a stack of 3 tiers of units *(12 feet).

Doors and windows would require a “shorty” or rectangular box to avoid square/short windows.

Does this have a name? Thanks for posting.