ICF vs SIPs: What Are the Differences?

Understanding the Basic Systems

Before diving into comparisons, it’s essential to understand what each system actually is and how it works. Both ICF and SIPs represent significant departures from traditional stick-frame construction, offering unique advantages and considerations.

What Are ICFs?

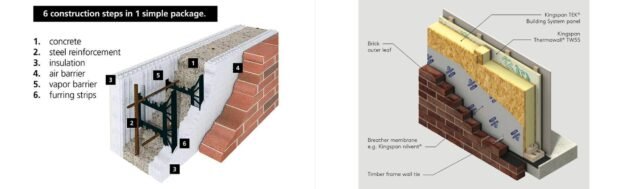

Insulated Concrete Forms consist of hollow foam blocks or panels—typically made from expanded polystyrene (EPS)—that interlock to form the shape of walls. Contractors place steel reinforcement within the cavities and then fill them with concrete. Once cured, the foam remains in place, providing permanent insulation on both sides of a solid concrete core. If you’re considering whether an ICF home is worth it in Ontario, understanding this fundamental structure is the first step.

ICF walls create a monolithic structure with exceptional thermal mass. The concrete core stores and releases heat slowly, moderating indoor temperatures naturally. This system excels in extreme climates like Ontario’s, where temperature swings are significant. Leading manufacturers like those featured in our guide to the best ICF brands offer various form configurations and insulation values to suit different applications.

What Are SIPs?

Structural Insulated Panels are factory-manufactured building components consisting of an insulating foam core—typically EPS or polyurethane—sandwiched between two structural facings, usually oriented strand board (OSB). These large panels, which can span entire walls or roof sections, arrive at the job site pre-cut and ready for assembly. The panels are structural, meaning they provide both the building’s skeleton and its insulation in one integrated system.

SIPs represent a panelized approach to construction. Rather than building walls stick by stick, contractors assemble large prefabricated components that go up quickly and precisely. The Structural Insulated Panel Association maintains standards for quality and performance, helping ensure consistent results across manufacturers.

Key Distinction: ICF is essentially reinforced concrete with permanent foam insulation, creating a solid mass wall. SIPs are sandwich panels that create a hollow wall cavity, more similar to conventional framing but with superior insulation and airtightness. This fundamental difference drives most of the performance and practical distinctions between the systems.

ICF Components

- EPS foam forms (2.5-12″ thick)

- Steel reinforcement (rebar)

- Concrete core (6-12″ typical)

- Plastic or metal ties connecting forms

- Furring strips for interior finish

SIP Components

- EPS or polyurethane foam core (4-12″ thick)

- OSB or plywood facings (7/16″-3/4″)

- Spline connections between panels

- Dimensional lumber for plates and beams

- Adhesive or mechanical fasteners

Cost Comparison

Budget considerations often determine which system makes sense for a project. Both ICF and SIPs cost more than conventional wood framing, but the premium varies significantly between the two systems and depends heavily on project specifics.

| Cost Factor | ICF | SIPs | Traditional Frame |

|---|---|---|---|

| Material Cost (per sq ft) | $11-16 | $9-13 | $8-12 |

| Labor Cost (per sq ft) | $9-14 | $6-10 | $7-10 |

| Premium vs Traditional | 10-15% | 5-10% | Baseline |

| Construction Speed | Moderate | Very Fast | Moderate |

| Crane Requirements | Optional | Usually Required | None |

Generally, SIPs represent a smaller upfront investment than ICF, though both exceed traditional framing costs. The faster installation of SIPs can reduce labor costs and shorten construction schedules, potentially offsetting some material premium. For detailed cost breakdowns, our ICF foundation cost calculator provides project-specific estimates.

ICF projects may require concrete pumping equipment and experienced concrete crews, adding cost in rural areas. SIP projects typically need crane rental for panel installation and precise factory cutting, which requires finalized plans earlier in the process. Changes after panel fabrication can be extremely expensive with SIPs, while ICF offers more flexibility during construction.

Both systems can reduce HVAC equipment costs due to superior envelope performance. Smaller, less expensive heating and cooling systems often suffice, partially offsetting the higher wall system costs. Additionally, both may qualify for energy efficiency incentives and potentially lower insurance premiums due to superior durability.

Energy Performance and Insulation

Both systems deliver excellent energy performance, but they achieve it through different mechanisms. Understanding these differences helps predict real-world performance in Ontario’s climate.

ICF Energy Characteristics

ICF walls typically provide R-values from R-22 to R-50 depending on form thickness and concrete core width. However, the R-value alone doesn’t tell the whole story. The concrete core provides substantial thermal mass—the ability to store and release heat slowly. This moderates temperature swings, reducing heating and cooling cycles.

During Ontario’s cold nights, the thermal mass releases stored heat slowly, keeping homes warmer longer. During hot summer days, the mass absorbs heat, preventing rapid interior temperature rises. This thermal flywheel effect means ICF homes maintain comfortable temperatures with less HVAC runtime. The Natural Resources Canada recognizes thermal mass as a significant factor in whole-building energy performance.

SIP Energy Characteristics

SIPs provide R-values typically ranging from R-14 to R-28 depending on core thickness. While lower than many ICF assemblies, SIPs eliminate thermal bridging almost entirely—the heat loss through framing members that plagues traditional construction. The continuous insulation core means no cold spots where studs would conduct heat.

SIPs excel at airtightness. The large panel construction with sealed joints creates exceptionally tight building envelopes, often achieving 1-2 air changes per hour at 50 pascals (ACH50)—well beyond code requirements. This airtightness prevents infiltration losses, which can account for 25-40% of heating costs in conventional homes. Professional installation from specialists like insulation contractors ensures optimal performance.

Real-World Energy Use: Both systems typically reduce heating and cooling costs by 40-60% compared to code-minimum construction. ICF’s thermal mass provides more consistent temperatures with less temperature swing, while SIPs’ superior airtightness minimizes air leakage losses. In practice, properly built examples of either system perform excellently in Ontario’s climate.

Structural Performance and Durability

How these systems perform over decades matters as much as initial construction. Durability, maintenance requirements, and structural capabilities differ significantly between ICF and SIPs.

ICF Structural Advantages

ICF creates reinforced concrete walls capable of resisting extreme forces. Wind resistance far exceeds code requirements—ICF walls can withstand hurricane-force winds and flying debris. While Ontario doesn’t face hurricanes, severe thunderstorms and occasional tornadoes do occur. ICF provides superior storm protection.

Fire resistance is exceptional. ICF walls achieve 4+ hour fire ratings, far exceeding code requirements. The non-combustible concrete and self-extinguishing foam mean fire cannot spread through walls. Insurance companies recognize this with premium reductions typically ranging from 5-15%.

ICF’s concrete core is impervious to rot, insects, and moisture damage. The structure will last 100+ years with virtually no maintenance. This durability makes ICF ideal for challenging sites or areas with high termite pressure. Working with experienced ICF contractors ensures proper detailing for maximum longevity.

SIP Structural Considerations

SIPs provide excellent structural performance for their weight. The stressed-skin panel design creates surprisingly strong assemblies that can span significant distances without intermediate supports. This enables open floor plans and creative architectural solutions.

However, SIPs are organic materials—wood facings and foam core. Proper detailing to prevent moisture intrusion is critical. Water damage can compromise structural integrity and promote mold growth. Quality installation with careful attention to flashing and air sealing prevents these issues, but the risk exists in ways it doesn’t with inorganic ICF.

Fire performance of SIPs meets code requirements but doesn’t approach ICF’s resistance. The OSB facings are combustible, though fire-retardant treatments and proper drywall installation provide adequate protection. Insurance premiums typically don’t see the reductions common with ICF construction.

ICF’s concrete core prevents termites, carpenter ants, and other wood-destroying insects from accessing structural components. SIPs’ wood facings can be vulnerable to insects if not properly treated and detailed. Ontario’s climate means lower termite pressure than southern regions, but carpenter ants remain a concern with any wood-based system.

Construction Process and Timeline

The construction process differs dramatically between these systems, affecting schedules, crew requirements, and complexity. Understanding these differences helps set realistic expectations and choose the right approach for your project timeline.

ICF Construction Process

ICF construction follows a methodical process. Contractors stack foam forms, install rebar reinforcement, brace the walls, and schedule concrete placement. The pour must be carefully controlled to prevent blowouts—forms failing under concrete pressure. After curing (typically 3-7 days), the forms become the substrate for interior and exterior finishes.

The process requires specialized knowledge but uses relatively simple tools and equipment. A small crew can make steady progress, though concrete placement days require coordination with ready-mix suppliers. Weather affects concrete work—cold temperatures require heating and protection, while extreme heat demands measures to prevent rapid drying.

Electrical and plumbing installations require planning. Trades cut chases in foam for wiring and pipes, or utilize pre-formed channels in some ICF systems. Changes during construction are manageable, though cutting concrete requires appropriate tools. The detailed ICF construction process requires experienced crews for best results.

SIP Construction Process

SIP installation happens rapidly once panels arrive. A crane lifts large panels into position, crews align and fasten them, and the structural shell can be complete in days rather than weeks. This speed reduces weather exposure and site time, potentially saving significant costs.

However, this speed requires extensive upfront planning. Panel manufacturers need finalized plans for factory cutting—changes after fabrication are expensive or impossible. Window and door openings, electrical chases, and even outlet locations should be determined before panel production begins.

Electrical installation follows specific procedures. Electricians run wiring through pre-cut chases in the foam core or use surface-mounted conduit. Future electrical changes require more effort than in traditional construction. Plumbing typically runs through interior partition walls rather than exterior SIP walls to avoid penetrating the envelope.

Speed Comparison: SIP walls can be erected in 3-5 days for a typical house, while ICF walls might take 2-3 weeks including form stacking, concrete placement, and curing. However, ICF offers more flexibility for on-site modifications, while SIP demands precise planning but rewards it with rapid assembly.

Maximum durability

100+ year lifespan with virtually no maintenance

Superior fire resistance

4+ hour fire ratings and non-combustible structure

Thermal mass benefits

Moderates temperature swings naturally

Extreme weather protection

Withstands severe storms and high winds

Construction flexibility

Can modify plans during building process

Fast construction

Shell completion in days, not weeks

Lower initial cost

5-10% premium vs 10-15% for ICF

Exceptional airtightness

Minimal air leakage with sealed panels

Long clear spans

Enables open floor plans without columns

Lighter weight structure

Reduced foundation requirements

Design Flexibility and Architectural Considerations

Both systems impose certain design constraints while enabling unique opportunities. Understanding these limitations and advantages during the design phase prevents costly surprises and allows you to leverage each system’s strengths.

ICF Design Considerations

ICF works best with relatively straightforward geometries. Rectangular walls, simple angles, and standard openings optimize efficiency. Complex curves, numerous corners, and intricate details increase costs and construction time significantly. Each corner or angle requires special forming and bracing.

However, ICF accommodates custom openings and details readily. Contractors can cut forms on-site to create varied window sizes or unusual configurations. This flexibility extends through construction—moving a window location or adding an opening, while not ideal, remains possible with ICF in ways it isn’t with SIPs.

SIP Design Requirements

SIPs demand finalized designs before panel fabrication begins. Window and door locations, sizes, and types must be determined early. Electrical outlet locations should be specified so chase can be cut at the factory. This front-loaded design process can actually benefit projects by forcing thorough planning early.

SIPs enable impressive architectural features. Large panels can create cathedral ceilings and dramatic open spaces efficiently. The strength-to-weight ratio allows creative designs that might be difficult or expensive with other systems. Roof systems particularly benefit from SIP construction, creating strong, insulated assemblies that span considerable distances.

Both systems benefit from designers experienced with their specific requirements. Many architectural firms specialize in high-performance construction and understand how to optimize designs for either system. Engaging knowledgeable designers early prevents problems and leverages each system’s advantages effectively.

Making Your Decision

Both ICF and SIPs deliver excellent energy performance, superior comfort, and long-term value compared to traditional construction. The choice between them depends on your specific priorities, budget, and circumstances rather than one being objectively better than the other.

Choose ICF if maximum durability, thermal mass benefits, fire resistance, and long-term structural integrity matter most to you. Accept the 10-15% cost premium and somewhat longer construction time in exchange for a virtually indestructible structure that will stand for generations with minimal maintenance. ICF excels for homeowners planning to stay long-term who value permanence and stability.

Choose SIPs if construction speed, initial cost, and design precision are priorities. Accept more demanding upfront planning and organic materials in exchange for rapid assembly, excellent airtightness, and a smaller cost premium. SIPs work well for projects with firm timelines, limited budgets, or designs that benefit from factory precision.

Either system will dramatically outperform traditional construction in Ontario’s climate. Both reduce energy consumption by 40-60%, provide superior comfort, and create durable, long-lasting homes. Work with experienced contractors familiar with your chosen system, invest in proper design, and you’ll enjoy the benefits of high-performance construction for decades to come.