Air Sealing an Ontario Home: Why ICF Makes It Easier (and Cheaper) to Do Right

Air Sealing an Ontario Home: Why ICF Makes It Easier (and Cheaper) to Do Right

Understanding Air Leakage and Why It Matters

Before examining ICF’s advantages, it’s crucial to understand what air sealing means and why it matters so much in Ontario’s climate. Air leakage—technically called infiltration and exfiltration—occurs when unconditioned outside air enters your home while conditioned indoor air escapes through cracks, gaps, and penetrations in the building envelope.

In Ontario’s heating-dominated climate, air leakage directly increases energy consumption. Every cubic foot of cold winter air that infiltrates must be heated to room temperature. Simultaneously, warm air escaping carries away the energy you paid to generate. This constant exchange forces heating systems to run longer and harder, wasting substantial energy and money.

Air leakage creates comfort problems beyond just energy waste. Drafts make rooms feel colder than their actual temperature, forcing you to increase thermostat settings. Uncontrolled air movement carries moisture that can condense in wall cavities, potentially causing mold, rot, and structural damage. The Natural Resources Canada identifies air sealing as one of the most cost-effective energy improvements homeowners can make.

Measuring Air Leakage: ACH50 Explained

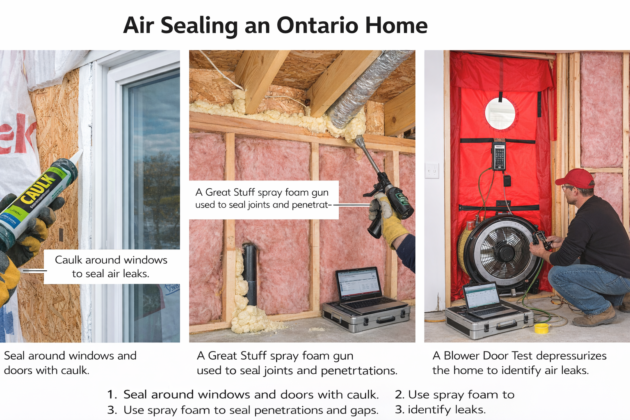

Building scientists measure air leakage using blower door tests. A powerful fan mounted in a doorway depressurizes the home to 50 Pascals—roughly equivalent to a 20 mph wind blowing on all sides simultaneously. The test measures how much air must be pumped out to maintain this pressure, expressing results as Air Changes per Hour at 50 Pascals (ACH50).

Lower ACH50 numbers indicate tighter homes. Ontario’s building code currently requires maximum 3.0 ACH50 for new construction—meaning the entire home’s air volume replaces three times per hour under test conditions. High-performance homes target 1.5 ACH50 or better. Passive House standard demands 0.6 ACH50, representing extremely tight construction. Understanding whether ICF homes are worth it requires recognizing their consistently excellent air sealing performance.

Ontario Climate Impact: In our heating-dominated climate, reducing air leakage from typical levels (5-8 ACH50) to high-performance levels (1-2 ACH50) saves 20-30% on heating costs. For a home spending $2,500 annually on heating, that’s $500-750 saved every year, indefinitely. These savings directly result from superior air sealing.

Air Leakage in Traditional Construction

Understanding traditional construction’s air sealing challenges highlights ICF’s advantages. Wood-frame homes contain thousands of potential leak points where air can infiltrate or escape.

Common Leakage Points in Wood Framing

- Bottom plate to foundation connections—gaps where wood framing meets concrete foundations allow substantial air leakage

- Top plate to ceiling connections—joist bays and penetrations for wiring, plumbing, and ductwork create numerous leaks

- Wall penetrations—every electrical outlet, switch, light fixture, and plumbing penetration potentially leaks air

- Window and door rough openings—gaps between framing and fenestration allow air movement

- Band joists—the transition between floors creates continuous leak paths around the building perimeter

- Rim joists and cantilevers—these complex framing areas are notoriously difficult to seal properly

- HVAC penetrations—ductwork, vents, and mechanical equipment create large openings requiring careful sealing

- Plumbing stack penetrations—pipes passing through multiple floors create vertical air channels

Each leakage point individually may seem insignificant. However, thousands of small gaps collectively create substantial air exchange. Research consistently shows that wood-frame homes rarely achieve better than 3-4 ACH50 without extraordinary attention to air sealing—and many perform far worse at 6-10 ACH50.

The Challenge of Sealing Wood Framing

Achieving truly tight construction with wood framing requires addressing every potential leak point. This demands:

- Sealed poly vapor barriers with all seams taped and all penetrations sealed with acoustic sealant

- Foam gaskets under all bottom plates and around all window/door rough openings

- Airtight electrical boxes or foam pads behind standard boxes

- Careful detailing of all mechanical penetrations with appropriate sealants

- Continuous air barrier maintained throughout the building envelope

This level of attention is expensive, time-consuming, and depends entirely on trades understanding and implementing proper procedures. In practice, most construction doesn’t achieve this standard. Even projects attempting rigorous air sealing often miss details that create leaks.

Achieving high-performance air sealing in wood-frame construction typically adds $2,000-4,000 in materials and labor costs. This includes air barrier systems, sealants, gaskets, tapes, and the additional labor for meticulous installation. Even with this investment, achieving ICF-level air tightness remains difficult.

How ICF Delivers Superior Air Sealing

ICF construction achieves exceptional air sealing not through extraordinary effort but through fundamental system characteristics that eliminate most leak paths inherent in wood framing. Understanding these advantages reveals why ICF consistently performs better.

The Monolithic Concrete Advantage

ICF walls consist of a continuous, monolithic concrete core. Unlike wood framing with thousands of joined pieces, ICF creates a solid mass with no internal air pathways. Once concrete cures, you have a virtually impermeable barrier to air movement—no gaps between studs, no spaces behind sheathing, no cavities for air to travel through.

This monolithic structure dramatically reduces leak points. Traditional framing might have a penetration every 16 inches where studs meet plates, plus every outlet box, switch, and framing intersection. ICF has none of these—just solid concrete with occasional intentional penetrations for utilities.

Integrated Air Barrier

The concrete itself serves as the air barrier—you don’t need separate poly sheets, tapes, or sealants throughout the walls. The foam forms permanently bonded to both sides of the concrete create additional air sealing. Modern ICF systems with interlocking joints minimize even the potential leaks between foam blocks.

Compare this to wood framing where the air barrier typically consists of polyethylene sheeting installed after framing, with every seam, penetration, and intersection requiring separate sealing. ICF’s integrated approach eliminates most opportunities for installation errors that compromise air sealing.

Reduced Penetration Count

ICF walls naturally have fewer penetrations than wood-frame walls. Electrical wiring typically runs in horizontal chases cut into interior foam rather than through the concrete core. This keeps penetrations to a minimum while simplifying installation. The various ICF brands available offer different strategies for running utilities, but all minimize wall penetrations compared to traditional framing.

Window and door installations benefit from ICF’s solid substrate. Rather than shimming and sealing rough openings in wood framing, windows attach directly to concrete with clear, solid attachment points. Proper installation with appropriate sealants and backer rods creates excellent seals that are easier to achieve than in wood framing.

Real-World Performance: Blower door testing consistently shows ICF homes achieving 1-2 ACH50 without extraordinary measures—simply through standard construction practices. Wood-frame homes require significant additional effort and cost to approach these results, and many never achieve them despite best intentions.

Comparing Air Sealing Costs: ICF vs Traditional

The economic case for ICF’s air sealing advantages becomes clear when examining what achieving equivalent performance costs in traditional construction.

| Air Sealing Component | ICF | Wood Frame |

|---|---|---|

| Primary Air Barrier | Included (concrete core) | $800-1,500 (poly, tape, sealants) |

| Bottom Plate Sealing | Included (monolithic) | $300-600 (foam gaskets) |

| Penetration Sealing | Minimal (foam chases) | $500-1,000 (boxes, seals) |

| Window/Door Sealing | Straightforward | $400-800 (extra labor, materials) |

| Band Joist Sealing | N/A (concrete) | $600-1,200 (foam, sealant, labor) |

| Additional Labor | None required | $800-1,500 |

| Total Air Sealing Cost | Included in system | $3,400-6,600 |

| Typical ACH50 Result | 1-2 ACH50 | 2.5-4 ACH50 (if done well) |

ICF delivers superior air sealing as an inherent benefit of the system. Wood framing can achieve good results, but only with significant additional cost and effort—and even then rarely matches ICF performance. When factoring air sealing costs into total project budgets, much of ICF’s apparent premium disappears.

Long-term savings compound these advantages. An ICF home achieving 1.5 ACH50 versus a wood-frame home at 3.5 ACH50 saves roughly $400-700 annually on heating costs in Ontario’s climate. Over a 25-year mortgage, that’s $10,000-17,500 in savings—more than covering any initial cost difference while delivering superior comfort.

Critical Air Sealing Details in ICF Construction

While ICF naturally achieves excellent air sealing, attention to specific details ensures optimal performance. Understanding and properly executing these critical junctions maximizes ICF’s inherent advantages.

Foundation to Wall Transition

The connection between ICF walls and the foundation requires proper detailing. If using ICF for both foundation and above-grade walls, the transition is straightforward—continuous concrete with minimal leak potential. When combining ICF with other foundation types, seal the joint between materials carefully with appropriate sealants or gaskets.

ICF basement walls connecting to traditional footings benefit from the continuous concrete pour that bonds walls directly to footings. This creates an inherently sealed connection. Projects using ICF instead of CMU basements gain significant air sealing advantages at this critical junction.

Top of Wall to Roof Connection

The wall-to-roof junction represents a critical air sealing point. With ICF walls, this connection is typically more straightforward than wood framing. The continuous concrete provides a solid, sealed substrate for roof attachment. However, proper flashing and sealing where roof systems attach remains important.

If using truss or rafter framing on ICF walls, seal the connection between the top plate attached to ICF and the roof system. This usually involves sealant, gaskets, or spray foam depending on specific details. The solid ICF surface makes this sealing easier than attempting to seal wood framing’s numerous joints and penetrations.

Window and Door Installation

Fenestration represents significant potential for air leakage in any construction system. ICF’s advantages here include solid, consistent rough openings and clear attachment points. Proper installation requires:

- Appropriate window bucks or frames attached securely to concrete

- Backer rod and sealant at all perimeter joints following manufacturer specifications

- Proper flashing integrated with exterior finish to prevent water intrusion

- Interior trim installed with sealant to complete the air barrier

The solid ICF substrate makes achieving proper window installation easier than shimming and sealing rough openings in wood framing. Consistent, solid backing provides reliable attachment and sealing surfaces.

Utility Penetrations

Every penetration through the building envelope—electrical, plumbing, HVAC—represents potential air leakage. ICF minimizes these penetrations by running most utilities through interior foam chases. When penetrations are necessary:

- Core drill clean, appropriately-sized holes through concrete

- Sleeve penetrations with PVC or similar material

- Seal around sleeves with appropriate expanding foam or sealant

- Ensure seal extends through the entire ICF thickness

The reduced number of required penetrations and solid substrate for sealing make utility penetrations less problematic in ICF than in wood framing’s cavity-filled walls.

While ICF naturally achieves excellent air sealing, proper installation remains important. Work with experienced contractors who understand critical details. Poor installation can compromise even ICF’s inherent advantages. Resources on finding qualified ICF contractors help ensure proper execution.

Testing and Verification: Blower Door Results

Blower door testing provides objective verification of air sealing performance. Understanding what these tests reveal helps appreciate ICF’s consistent advantages.

Typical ICF Performance

Well-built ICF homes routinely achieve 1.0-2.0 ACH50 without extraordinary measures. Many exceed this, reaching 0.5-1.0 ACH50 with careful attention to details. This performance rivals Passive House standards and far exceeds code requirements—all from standard ICF construction practices.

Compare this to wood-frame construction where achieving 2.5-3.0 ACH50 represents good performance requiring careful work. Many code-built wood-frame homes test at 4.0-6.0 ACH50 or worse, indicating substantial air leakage and energy waste.

When to Test

Consider blower door testing at two stages: rough-in and final. Rough-in testing before interior finishing allows identifying and correcting leaks while access is easy. Final testing verifies completed performance and can identify issues introduced during finishing.

For ICF homes, pre-drywall testing often reveals excellent results already. Most leaks discovered involve utility penetrations or window installations—issues easily corrected before finishing. This contrasts with wood framing where rough-in testing frequently reveals numerous air sealing deficiencies throughout the structure.

Energy Savings Reality: An ICF home achieving 1.5 ACH50 versus a code-minimum home at 3.0 ACH50 saves approximately $500-800 annually in heating costs in Ontario. That’s $12,500-20,000 over 25 years—substantial savings directly attributable to superior air sealing.

The Air Sealing Advantage

ICF construction delivers exceptional air sealing not through extraordinary effort or expense, but as an inherent characteristic of the system. The monolithic concrete core, integrated foam forms, and minimal penetration count create buildings that are naturally tight—achieving performance levels that wood framing struggles to match even with significant additional investment.

This air sealing advantage translates directly to lower energy bills, improved comfort, better indoor air quality, and increased durability. In Ontario’s heating-dominated climate, reducing air leakage from typical levels to ICF-achieved levels saves $400-800 annually on heating costs. Over decades of occupancy, these savings dramatically exceed any initial cost premium for ICF construction.

Beyond energy savings, ICF’s superior air sealing creates more comfortable homes with fewer drafts, more consistent temperatures, and quieter interior environments. The moisture control benefits of controlled air exchange protect building durability while maintaining healthy indoor environments. These quality-of-life improvements are difficult to quantify financially but profoundly impact daily living experience.

For homeowners committed to energy efficiency, comfort, and long-term value, ICF’s air sealing advantages represent compelling benefits. While you can achieve good air sealing with traditional construction through extraordinary attention to detail and significant expense, ICF delivers superior results almost automatically. This inherent performance advantage makes ICF an intelligent choice for anyone prioritizing energy efficiency and comfort in Ontario’s demanding climate.

Scroll sideways to see more. Cards stay the same height (no messy uneven rows).