ICF vs CMU (Cinder Block) for a Basement—What’s Better?

ICF vs CMU (Cinder Block) for a Basement—What’s Better?

Understanding the Systems

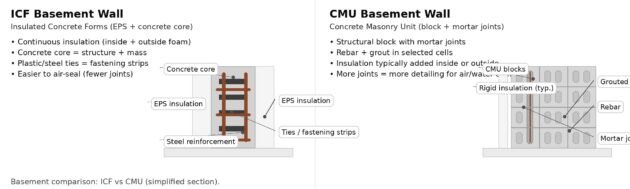

Before comparing performance and costs, it’s important to understand what each system actually is and how construction proceeds. The fundamental differences between these systems drive all their relative advantages and limitations.

CMU Block Construction

Concrete masonry units—commonly called cinder blocks or concrete blocks—have been the standard basement construction method for decades. Masons stack hollow concrete blocks, fill vertical cells with concrete and rebar for reinforcement, and create walls that provide excellent structural strength. The blocks themselves are 8 inches wide typically, with hollow cores that reduce weight and material costs.

Traditional CMU construction creates uninsulated walls. To meet modern energy codes, builders must add insulation—either on the exterior (less common for basements), in the block cores (limited effectiveness), or on the interior with framed walls and fiberglass or rigid foam. This additional step adds cost, reduces usable space, and creates potential moisture issues if not detailed properly.

CMU basement construction has proven itself over generations. The system works, contractors understand it thoroughly, and costs are predictable. Most residential masons in Ontario have extensive CMU experience, making it easy to find qualified trades. For accurate cost estimates, use our concrete footings calculator to understand foundation costs before the walls go up.

ICF Basement Construction

Insulated Concrete Forms represent a newer approach, though the technology has been proven for decades. Hollow foam blocks or panels stack to form the basement walls. Steel reinforcement is placed throughout, and concrete is pumped into the cavities, creating a solid reinforced concrete core with permanent foam insulation on both sides.

The integrated insulation distinguishes ICF from CMU fundamentally. Rather than adding insulation as a separate step, it’s built into the wall system from the start. This creates superior thermal performance, eliminates interior finishing complications, and maximizes usable basement space. Understanding ICF foundation costs helps budget appropriately for this modern approach.

ICF basements integrate seamlessly with ICF above-grade walls for homeowners planning comprehensive custom ICF home construction. However, ICF basements also work perfectly well with traditional wood-frame or any other above-grade construction system.

Ontario Code Compliance: Both systems easily meet structural requirements in the Ontario Building Code. However, meeting energy efficiency standards requires adding significant insulation to CMU basements, while ICF basements exceed code requirements inherently. Stay current with Ontario Building Code changes to ensure your project meets all current standards.

Cost Comparison

Budget drives many construction decisions, and basement systems are no exception. While ICF costs more initially than bare CMU, the gap narrows significantly when you account for the insulation, finishing, and long-term energy costs.

| Cost Component | CMU Block | ICF |

|---|---|---|

| Materials (per sq ft of wall) | $8-12 | $12-16 |

| Labor (per sq ft of wall) | $7-11 | $8-13 |

| Insulation & Finishing | $6-10/sq ft additional | Included |

| Total Wall Cost | $21-33/sq ft | $20-29/sq ft |

| R-Value Achieved | R-10 to R-15 typical | R-22 to R-30 typical |

| Annual Heating Cost Difference | Baseline | 30-50% lower |

When you properly insulate a CMU basement to modern standards—using 2×4 framing with fiberglass or rigid foam on the interior—the total cost approaches or even exceeds ICF. Yet the ICF basement delivers superior R-values, eliminates thermal bridging through studs, maximizes usable space, and provides integrated water resistance.

For a 1,500 square foot basement (approximately 600 linear feet of 8-foot walls, or 4,800 sq ft of wall area): CMU with proper insulation and finishing runs $100,000-$158,000. ICF ranges from $96,000-$139,000. When factoring in superior performance and fewer finishing steps, ICF often costs less while delivering significantly better results.

Long-Term Cost Considerations

Beyond initial construction, operating costs diverge significantly. ICF basements’ superior insulation reduces heating costs substantially. Over a 25-year mortgage, a typical ICF basement saves $8,000-15,000 in heating costs compared to a minimally-insulated CMU basement. These savings continue for the life of the home, making ICF an increasingly attractive investment.

Maintenance costs also favor ICF. The integrated waterproofing and lack of interior wood framing means no moisture-related issues like mold, rot, or insulation degradation. CMU basements with interior framing can experience these problems if moisture infiltration occurs—and in Ontario’s wet climate, that’s a real concern.

Insulation and Energy Performance

Ontario’s cold winters make basement insulation critical. Uninsulated or poorly insulated basements waste tremendous energy and create uncomfortable living spaces. The insulation difference between these systems dramatically affects comfort and operating costs.

CMU Insulation Challenges

Bare CMU blocks provide essentially no insulation—perhaps R-1 to R-2. Meeting modern building codes requires adding substantial insulation. The most common approach involves building a 2×4 stud wall against the interior, filling it with fiberglass batts, and covering with drywall. This achieves R-12 to R-15 but consumes 6 inches of interior space around the entire basement perimeter.

This approach creates several problems. First, thermal bridging through wood studs reduces effective R-value by 20-30%. Second, the stud cavity creates an air gap where moisture can accumulate, potentially leading to mold. Third, any water seepage through the block wall goes undetected until it damages interior finishes. Fourth, you lose significant usable space—in a 30×40 basement, interior insulation consumes roughly 200 square feet.

Rigid foam insulation applied to interior block walls addresses some issues but creates others. It eliminates stud thermal bridging and resists moisture better than fiberglass. However, attaching finishes to foam requires furring strips (thermal bridging returns), and foam itself represents embodied carbon and potential off-gassing concerns.

ICF Insulation Advantages

ICF basements provide R-22 to R-30 or higher depending on foam thickness. This insulation is continuous—no thermal bridging, no gaps, no compression. The foam remains on the exterior of the concrete (below grade), preventing thermal losses while keeping the concrete mass inside the thermal envelope.

The thermal mass effect matters significantly in basements. Concrete’s heat capacity moderates temperature swings, creating naturally stable environments. In ICF construction, this mass sits inside the insulation, maximizing the benefit. In insulated CMU construction, the mass sits outside the insulation (if exterior) or is interrupted by stud framing (if interior), reducing effectiveness.

ICF’s superior envelope tightness prevents air leakage—a major source of basement energy losses. The monolithic concrete pour with foam forms creates essentially airtight walls. CMU construction with mortared joints and subsequent insulation installation rarely achieves similar airtightness.

Real-World Performance: Independent testing consistently shows ICF basements using 40-60% less energy for conditioning than comparably-sized CMU basements with standard interior insulation. In Ontario’s heating-dominated climate, this translates to $300-600 annual savings for a typical basement, every year, indefinitely.

Waterproofing and Moisture Management

Basements in Ontario face constant moisture pressure from groundwater, especially in spring and after heavy rains. How wall systems handle moisture significantly affects durability, maintenance, and livability.

CMU Waterproofing Requirements

CMU walls are porous. Water penetrates through mortar joints, block faces, and any cracks. Proper waterproofing requires multiple steps: parge coating the exterior, applying waterproof membrane, installing drainage board, and ensuring proper footing drainage. Even with meticulous application, CMU walls can experience moisture intrusion.

Interior moisture in CMU basements with framed insulation walls creates serious problems. Water that seeps through blocks gets trapped in the stud cavity, potentially leading to mold, rot, and insulation damage. Detecting these problems early is difficult since they occur behind finishes. By the time damage becomes visible, significant deterioration may have occurred.

The Health Canada guidelines emphasize moisture control in basements to prevent mold growth. CMU construction requires vigilant water management, proper grading, and functional drainage systems to keep basements dry.

ICF Moisture Resistance

ICF walls resist water intrusion inherently. The monolithic concrete core has no mortar joints where water can penetrate. The exterior foam protects the concrete from freeze-thaw damage while acting as a drainage plane. Standard waterproofing membranes apply easily to the smooth foam surface, creating reliable water barriers.

If moisture does find its way through, ICF’s lack of interior wood framing means no rot or mold substrate. The concrete and foam are inorganic—they don’t support mold growth. Any moisture that penetrates can dry through the interior face without causing damage. This forgiveness makes ICF basements more resilient to the inevitable moisture challenges Ontario basements face.

Finishing ICF basement walls is straightforward. Furring strips attach directly to plastic ties embedded in the foam forms, providing a nailing surface for drywall without creating problematic cavities. This simplified finishing saves money while eliminating moisture trap spaces.

Regardless of wall system choice, proper perimeter drainage is essential. Install weeping tile around the footings, connect to daylight or a sump pump, and ensure positive grading away from the foundation. Even the best waterproofing systems benefit from reducing hydrostatic pressure through effective drainage.

Construction Process and Timeline

How quickly and easily walls go up affects overall project timelines and costs. Labor availability, weather sensitivity, and construction complexity all vary between these systems.

CMU Construction Process

CMU construction follows a time-tested process. Masons stack blocks course by course, filling vertical cells with concrete and installing rebar for reinforcement. The work proceeds at a predictable pace—a crew can typically complete a residential basement in 3-5 days of actual masonry work, weather permitting.

Finding qualified CMU masons is relatively easy in Ontario. The trade is well-established, and most contractors have decades of experience. This familiarity means fewer surprises and reliable scheduling. However, masonry work is labor-intensive and weather-sensitive—extreme cold, rain, or high winds can halt progress.

After walls are complete and cured, separate trades install waterproofing, insulation, and interior framing. Each step requires coordination and adds time to the schedule. Total time from starting walls to ready-to-finish basement typically runs 2-3 weeks.

ICF Construction Process

ICF installation moves faster than CMU once crews have experience. Contractors stack lightweight foam forms, install rebar, brace the walls, and schedule concrete placement. A typical basement pours in one day, and after curing (3-7 days), the structure is ready for finishing.

Finding experienced ICF contractors requires more effort than finding masons. While ICF expertise is growing, it’s not yet as widespread as traditional masonry. Working with specialists like ICF contractors ensures proper installation and optimal performance.

ICF construction consolidates steps. Waterproofing, structural walls, and insulation happen together, eliminating the sequential trades required for CMU. This integration reduces coordination complexity and shortens schedules—ICF basements can be ready for finishing within 10-14 days from starting walls.

Weather Advantage: ICF construction proceeds in a wider range of weather conditions than CMU. The foam forms protect concrete during curing, allowing winter construction with proper precautions. CMU work often pauses during cold months, potentially delaying projects significantly in Ontario’s long winters.

✓ ICF Basement Advantages

- Superior insulation (R-22 to R-30+) built-in

- No interior framing or insulation needed

- Maximizes usable basement space

- Better moisture resistance and durability

- Faster overall construction timeline

- 40-60% lower heating costs

- No thermal bridging or air leakage

- Integrated waterproofing

- Superior soundproofing (STC 50+)

- Comparable or lower total cost when finished

× ICF Basement Challenges

- Higher material costs than bare CMU

- Requires experienced ICF contractors

- Less familiar to building inspectors in some areas

- Requires proper bracing during concrete placement

- Limited ability to modify after concrete curing

✓ CMU Basement Advantages

- Widely available experienced masons

- Lower bare wall material costs

- Familiar to inspectors and contractors

- Proven track record over generations

- Easier to modify openings after construction

× CMU Basement Challenges

- Requires separate insulation and finishing

- Reduces usable basement space (interior insulation)

- Lower R-values even when insulated

- Thermal bridging through studs

- More moisture intrusion risk

- Higher long-term energy costs

- More complex waterproofing requirements

- Weather-sensitive construction

- Higher total cost when properly finished

The Verdict: Which Is Better?

For most Ontario homeowners, ICF delivers superior value for basement construction. While material costs run slightly higher, the integrated insulation, simplified finishing, and long-term energy savings create compelling advantages. ICF basements are warmer, drier, more comfortable, and less expensive to operate than CMU basements—even properly-insulated ones.

The total installed cost difference is minimal or nonexistent. When you account for insulation, framing, and finishing required for CMU, costs converge or even favor ICF. The superior performance—R-22+ insulation, no thermal bridging, excellent moisture resistance—makes ICF the better investment for most projects.

CMU remains a viable choice for specific situations: projects in remote areas where ICF expertise is unavailable, homeowners who already have experienced masonry crews lined up, or renovations where matching existing construction makes sense. For new construction with access to qualified ICF contractors, however, ICF represents the modern, high-performance choice that will deliver comfort and value for generations.

The construction industry is moving toward higher performance standards. Energy codes will continue tightening, making efficient building envelopes increasingly important. ICF basement construction positions your home ahead of these trends, creating a foundation that exceeds current standards while providing superior comfort and lower operating costs for the life of your home. In Ontario’s demanding climate, that investment in performance pays dividends every heating season, year after year.

Scroll sideways to see more. Cards stay the same height (no messy uneven rows).